This is tough to describe in words.

First thing to learn is that 80% of

the torque applied is used to overcome

friction, so dry vs oiled threads is very

important.

The next thing to learn is that torque

as a function of degrees of rotation is

like a hockey stick. As soon as you

hit the inflection point on the curve

you are where you want WRT stretch.

Oh yeah - always use a flat washer

with the nut - and don't reuse flat

star lock washers.

Piston Engine: Horsepower + Torque

-

Strega

- Posts: 384

- Joined: Tue May 05, 2015 1:43 am

When you tighten a nut on a bolt, you are actually applying a preload to the bolt..the actual preload applied is much more important than the torque of the nut.

I actually made a jig to measure the bolt stretch on connecting rod bolts (used a dial indicator) ...

Ever wonder why in a lot of german and japanese service manuals there is a small torque spec, and then a "rotational" spec?

Im sure all the avcan experts here like Mr Crunch will tell you Im wrong though,

I actually made a jig to measure the bolt stretch on connecting rod bolts (used a dial indicator) ...

Ever wonder why in a lot of german and japanese service manuals there is a small torque spec, and then a "rotational" spec?

Im sure all the avcan experts here like Mr Crunch will tell you Im wrong though,

-

woodzi

Correct. The torque specified is that which is theoretically required to reach the preload you want. That is why lubricated vs. dry is important.

The preload is important because the whole idea is to keep the parts together and sealed and to avoid fatigue failure of the fasteners.

The preload is important because the whole idea is to keep the parts together and sealed and to avoid fatigue failure of the fasteners.

-

Colonel

- Posts: 3450

- Joined: Wed Apr 29, 2015 10:31 am

This is probably too much detail but ...

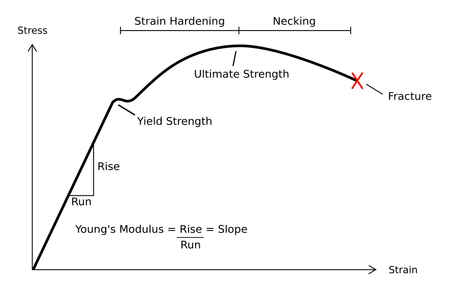

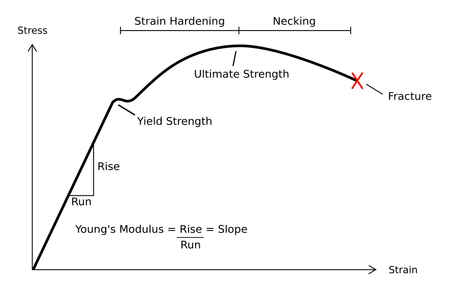

First we start with Young's Modulus and a stress vs strain graph

When we distort a material it is elastic at first - it will bounce

back after the load is removed

However if we continue to increase the load the deformation is

plastic - the material permanently yields, even after the load is

removed

Against that backdrop ... I aim for elastic deformation (stretch)

of the fastener - it can be reused. I can feel the elastic stretch

of the fastener in my fingertips. So can any master mechanic,

whom also doesn't need a torque wrench.

With plastic deformation of the fastener you must check against

the Table Of Limits in the Overhaul Manual to see if the fastener

(eg through bolt) is still serviceable.

Some fasteners like connecting rod bolts are "use once".

If you understand basic strength of materials (1st year

engineering) the rest is obvious.

https://en.wikibooks.org/wiki/Strength_of_Materials

First we start with Young's Modulus and a stress vs strain graph

When we distort a material it is elastic at first - it will bounce

back after the load is removed

However if we continue to increase the load the deformation is

plastic - the material permanently yields, even after the load is

removed

Against that backdrop ... I aim for elastic deformation (stretch)

of the fastener - it can be reused. I can feel the elastic stretch

of the fastener in my fingertips. So can any master mechanic,

whom also doesn't need a torque wrench.

With plastic deformation of the fastener you must check against

the Table Of Limits in the Overhaul Manual to see if the fastener

(eg through bolt) is still serviceable.

Some fasteners like connecting rod bolts are "use once".

If you understand basic strength of materials (1st year

engineering) the rest is obvious.

https://en.wikibooks.org/wiki/Strength_of_Materials

-

Colonel

- Posts: 3450

- Joined: Wed Apr 29, 2015 10:31 am

[b]Re-use Of Fasteners[/b]

This is a terribly important topic, and you

need to learn about it from someone who

knows a lot more about it than I do.

Here are some rules I live by, which are

sure to enrage the AME's:

- flat washers can generally be re-used

as long as they are not scarred or distorted.

Always use at least a flat washer with a nut.

For non-structural applications, I have

had great success using those clear plastic

washers to stop screws vibrating loose.

- never re-use a flat star lock washer,

either internal or external. They are

"use-once" like a condom.

Typically a lock washer will be used with

a flat washer (eg on a magento stud) to

reduce the probability of the nut backing off.

Always replace star lock washers with new

and throw the old ones in the garbage.

Don't let the homebuilders get ahold of them.

- split ring lock washers can be re-used

as long as they are not squished flat.

Like a new pair of tits, they must be

perky.

- fiber nuts and metal stop nuts can be

re-used as long as they [b]retain adequate

tension[/b]. Any doubt in your mind, toss

them in the garbage. Keep a good stock

of new ones on hand, in common sizes.

Be aware that fiber nuts in high heat

areas (eg forward of firewall, landing

gear) will have a shortened life and will

probably need replacement each time.

Try not to use fiber nuts in high heat areas

but depressingly, engine and airframe

manufacturers do. Look at a new airplane

sometime with the cowl off.

- bolts can generally be reused as long

as they have not suffered plastic deformation

and if used with metal stop nuts, have

adequate meat left on the threads.

Again, any doubt in your mind, toss it in the

garbage and use a new one. Again, the key

is to have a good stock of common AN hardware

on hand.

This is a terribly important topic, and you

need to learn about it from someone who

knows a lot more about it than I do.

Here are some rules I live by, which are

sure to enrage the AME's:

- flat washers can generally be re-used

as long as they are not scarred or distorted.

Always use at least a flat washer with a nut.

For non-structural applications, I have

had great success using those clear plastic

washers to stop screws vibrating loose.

- never re-use a flat star lock washer,

either internal or external. They are

"use-once" like a condom.

Typically a lock washer will be used with

a flat washer (eg on a magento stud) to

reduce the probability of the nut backing off.

Always replace star lock washers with new

and throw the old ones in the garbage.

Don't let the homebuilders get ahold of them.

- split ring lock washers can be re-used

as long as they are not squished flat.

Like a new pair of tits, they must be

perky.

- fiber nuts and metal stop nuts can be

re-used as long as they [b]retain adequate

tension[/b]. Any doubt in your mind, toss

them in the garbage. Keep a good stock

of new ones on hand, in common sizes.

Be aware that fiber nuts in high heat

areas (eg forward of firewall, landing

gear) will have a shortened life and will

probably need replacement each time.

Try not to use fiber nuts in high heat areas

but depressingly, engine and airframe

manufacturers do. Look at a new airplane

sometime with the cowl off.

- bolts can generally be reused as long

as they have not suffered plastic deformation

and if used with metal stop nuts, have

adequate meat left on the threads.

Again, any doubt in your mind, toss it in the

garbage and use a new one. Again, the key

is to have a good stock of common AN hardware

on hand.

-

- Similar Topics

- Replies

- Views

- Last post

-

- 0 Replies

- 482 Views

-

Last post by Colonel

-

- 18 Replies

- 3500 Views

-

Last post by Colonel

-

- 0 Replies

- 2778 Views

-

Last post by Scudrunner